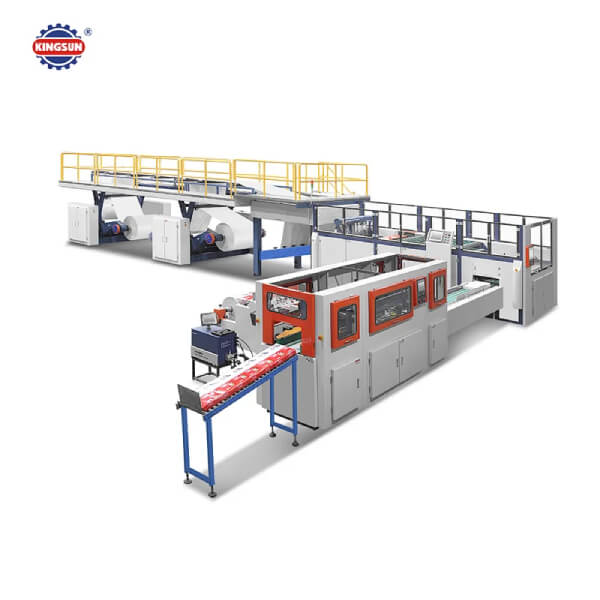

Automatic A3 Paper Cutting A4 Paper Making Machine

A3 paper cutting machine, A4 Copy paper making machine or A3 or A4 paper cutting and packaging machine is kind of new advanced equipment for converting A4 copy paper. With features of high automation and low labor intensity. It is an integration of electric, PLC controlling system and mechanical automation.

The whole process consists of paper roll unwinding, slitting, sheeting, counting, conveying, reams ejecting, packaging and delivery. It can made according to buyer request, 4 paper rolls 4 or 5 cuts, or 5 paper rolls 4 or 5 cuts etc, so can acheive the different production capacity.

Equipment Details

Description

A3 paper cutting machine, A4 Copy paper making machine or A3 or A4 paper cutting and packaging machine is kind of new advanced equipment for converting A4 copy paper. With features of high automation and low labor intensity. It is an integration of electric, PLC controlling system and mechanical automation.

The whole process consists of paper roll unwinding, slitting, sheeting, counting, conveying, reams ejecting, packaging and delivery. It can made according to buyer request, 4 paper rolls 4 or 5 cuts, or 5 paper rolls 4 or 5 cuts etc, so can acheive the different production capacity.

Main Structures:

1) Shaftless and lifting shelves of the ground controlling system—— Two sets

2) Advanced tension controlling system —— Four sets.

3) Four sets of anti-warping mechanisms——Four sets.

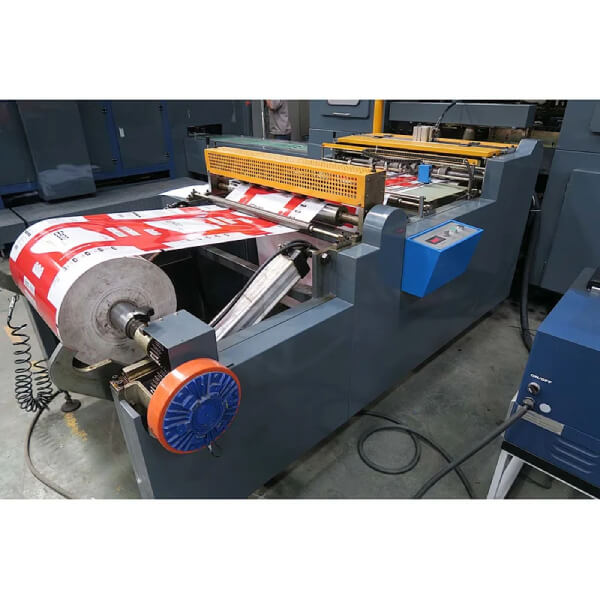

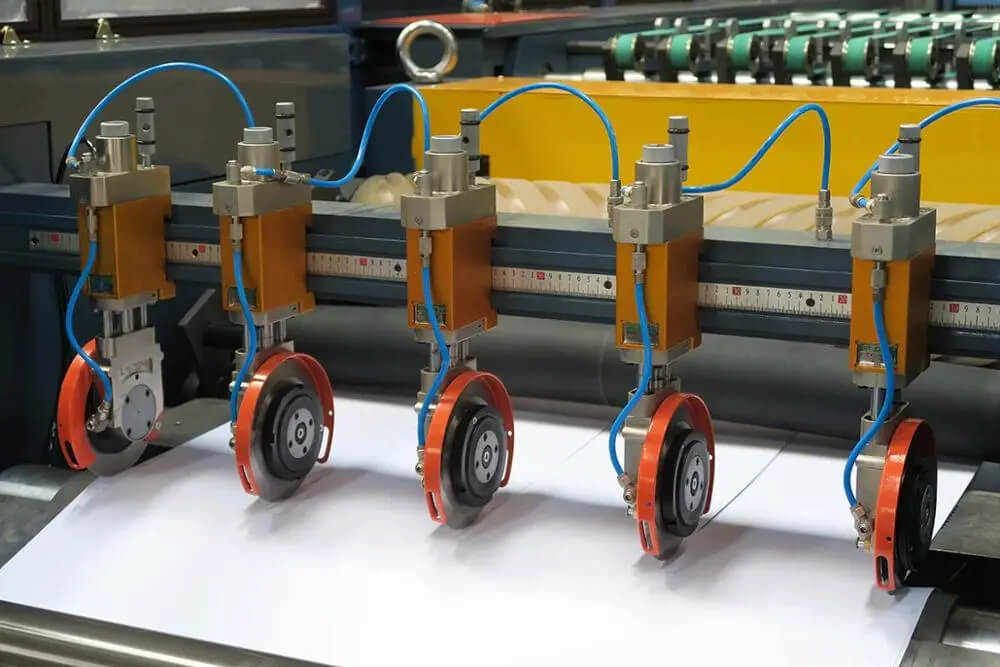

4) Longitudinal slitting knife groups——Five sets.

5) Simultaneous sheeting knife group—–One set.

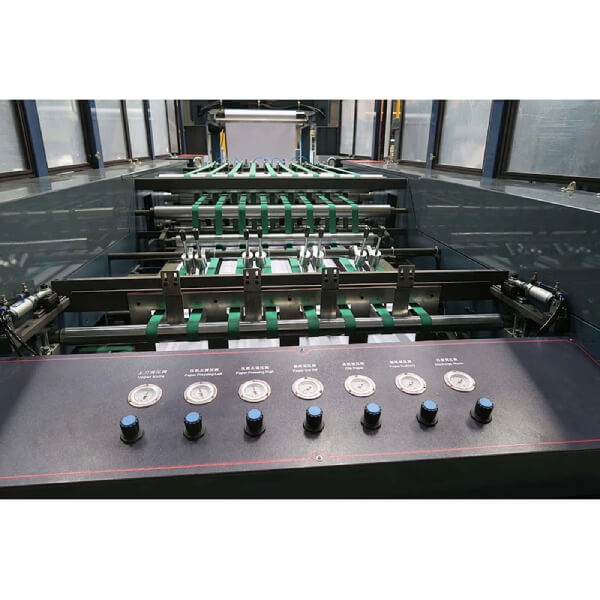

6) High-speed paper feeding system—–Three sets.

7) Low-speed paper feeding system—–Two sets

8) Waste paper automatic discharging system—–One set.

9) Making papers in order of 2D vibration, the cylinder lifting device of reams of paper collecting system——One set.

10) PLC reams of paper counting device——One set.

11) Reams of paper longitudinally discharging equipment—–One set.

12) PLC failure alarm and machine haulting system and PLC controlling equipment ——One set.

All above features will be various according to different design and models.

Main Specifications:

|

Gross width |

850mm |

|

Net width |

840mm |

|

Number of cutting |

4cuttings-A4 210mm(width) depends on sizes |

|

Diameter of paper roll |

400-1200mm |

|

Paper core ID |

3”(76.2mm)-6”(152.4mm) |

|

Paper weight |

60-100gsm |

|

Length of paper cutting |

A4(297mm) |

|

Paper quantity |

0-500 pages |

|

Ream height |

Max 65mm |

|

Designing speed of paper sheeting |

160m/min |

|

Times of sheet cutting |

538/min |

|

Cycle time of ream exhausted |

4.3/min |

|

Real speed of paper sheeting |

130m/min |

|

Times of paper cutting |

437/min |

|

Cycle time of ream exhausted |

3.5/min(14 reams/min) |

|

Max thickness of paper sheeting |

Max 400gsm (4×100gsm) |

|

Paper sheeting accuracy |

±0.2mm(compromise error) |

|

Paper sheeting condition |

1.Speed not change 2.Paper roll with no breakage 3. Qulified paper roll. |

|

Transmission |

AC Frequency converter, stepless speed regulating |

|

Main power source |

3phase/380v/50Hz or special made |

|

Adjustable voltage |

220V AC/22V DC |

|

Installed capacity |

35KW |

|

Air consumption |

300NL/min |

|

Pneumatic pressure |

6bars |

|

Overall dimension(sheeting machine): |

15000×2750×2100mm(Depends on models) |

|

Weight: |

12000kgs(Depends on models) |

|

Overall dimension(packing machine): |

6000×3400×1600mm(Depends on models) |

|

Weight: |

25000kgs (Depends on models) |

For more details please contact Kingsun Machinery Team, this machine is special made as per customer requirement.